WSS Blog

Follow our latest updates and thoughts on our industry2026 Best Pallet Storage Solutions for Efficient Warehouse Management?

In today’s competitive warehouse environment, efficient pallet storage solutions are more critical than ever. With increasing inventory demands, warehouse managers face numerous challenges. The need for optimized space, faster access, and improved organization is essential.

Pallet storage systems play a vital role in achieving these goals. They not only enhance organization but also streamline the picking process. However, finding the right storage solution can be daunting and often requires careful consideration. Poor choices can lead to wasted space or inefficiencies.

Evaluating various options is important as each warehouse has unique needs. There are numerous solutions available, yet not all might fit every operation. Reflecting on current processes and identifying areas for improvement is key. Making strategic decisions in pallet storage ultimately contributes to overall warehouse success.

Innovative Pallet Racking Systems for Optimized Space Utilization in 2026

In 2026, efficient warehouse management relies heavily on innovative pallet racking systems. Modern warehouses face space constraints. According to industry reports, effective storage solutions can increase space utilization by up to 30%. Leveraging vertical space is crucial. High-density racking systems allow for better use of height, transforming areas that may seem underutilized.

Pallet racking systems such as drive-in and push-back solutions have gained popularity. These systems not only maximize space but also streamline access to stored goods. Statistically, implementing advanced racking can boost picking efficiency by as much as 25%. However, the transition to these systems requires careful planning. Not all warehouses can adapt without reevaluating existing infrastructure.

Automation is also transforming pallet storage. Automated systems can enhance accuracy and reduce labor costs. Yet, integrating automation may lead to unexpected challenges. Workers need training. Traditional processes may need rethinking, which can be daunting. Balancing innovation with practicality will be vital for successful implementation.

2026 Best Pallet Storage Solutions - Warehouse Efficiency

Impact of Automated Storage Solutions on Warehouse Efficiency and Productivity

The rise of automated storage solutions has transformed warehouse efficiency significantly. According to a recent industry report, businesses implementing these technologies see productivity gains of up to 40%. Such advancements streamline operations and reduce labor costs. Automated systems can quickly retrieve and store pallets, minimizing time spent on manual handling.

However, adopting automation is not without challenges. Integration complexities can disrupt existing workflows. Some workers may resist changes, leading to morale issues. Despite these hurdles, companies that embrace automation report better space utilization. A study found that effective automated systems could increase storage density by 30%. This shift not only creates room for more products but also reduces operational costs.

Moreover, automation technologies enable real-time inventory tracking. This capability ensures accuracy in stock levels, reducing the risk of overstock or stockouts. Yet the cost of initial investment can be daunting for smaller businesses. The balance between the costs and long-term gains remains a debate. While many companies thrive post-automation, others face difficult transitions. It's crucial to weigh these factors when considering such a shift in warehouse management.

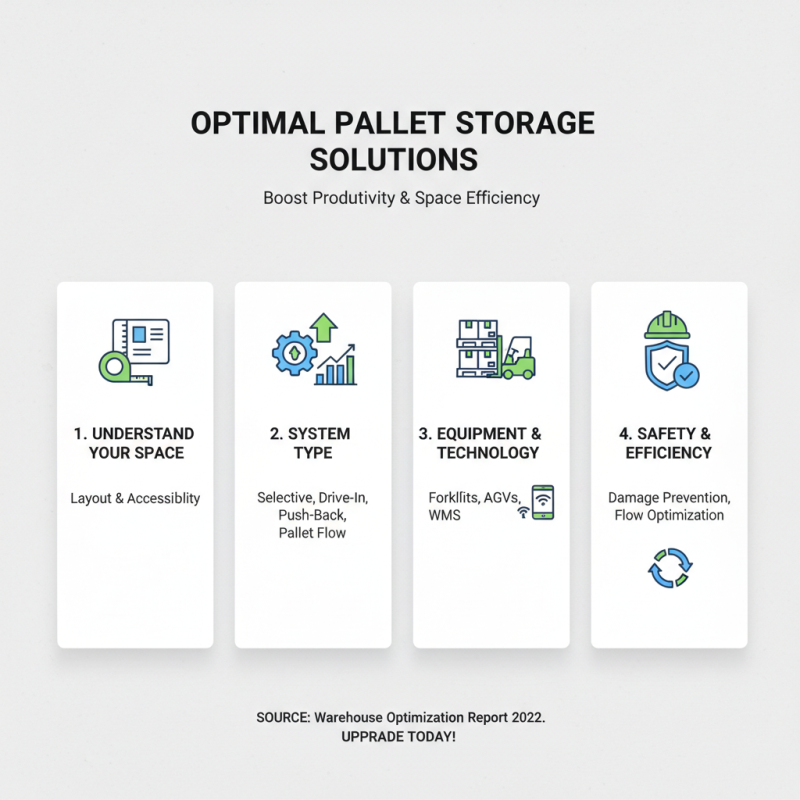

Key Factors in Selecting the Best Pallet Storage Solutions for Your Warehouse

Selecting the best pallet storage solutions for your warehouse involves several key factors. Understanding your space is essential. The layout impacts efficiency and accessibility. A well-organized warehouse can boost productivity by 25%, according to the Warehouse Optimization Report 2022.

Pallet racking is a common choice. It maximizes vertical space, allowing for more inventory without expanding the footprint. However, it requires careful consideration of safety standards. Overloading racks can lead to accidents, which could be costly. Regular inspections are vital to prevent such issues.

Tips: Always assess your workflow before choosing storage solutions. High-density storage may not suit every operation. Flexibility in design is important. Consider solutions that can adapt to changing inventory needs. Lastly, train staff on safe pallet handling to mitigate risks and maintain efficiency. Invest in technology for real-time inventory tracking to avoid stock discrepancies.

Latest Trends in Pallet Storage Technologies and Their Economic Benefits

Pallet storage technologies are evolving rapidly. Recent reports indicate that automated storage solutions have increased efficiency by up to 30%. This is crucial for managing warehouse space effectively. As demand for goods rises, optimizing storage becomes vital for businesses.

Adoption of new technologies, like automated guided vehicles (AGVs), is also rising. AGVs enhance the movement of pallets across the warehouse. Studies show that companies utilizing AGVs see a 15% reduction in labor costs. However, the initial investment can be significant. This creates a challenge for smaller businesses.

Moreover, smart pallet systems offer real-time tracking. They improve inventory management, reducing errors. A logistic report noted that real-time data can decrease stock discrepancies by 25%. Yet, integration with existing systems can pose difficulties. Many firms struggle with the transition. Embracing these advancements is essential but often requires reflection on current practices.

Case Studies: Successful Implementations of Pallet Storage Solutions in 2026

In 2026, companies have increasingly turned to innovative pallet storage solutions to enhance warehouse efficiency. A recent study revealed that logistics firms improved their space utilization by 30% through advanced racking systems. These systems support various pallet sizes, which creates versatility in storage options. One case showed a distribution center that used drive-in racking, significantly increasing its storage capacity while minimizing aisles. They reported a 25% reduction in picking time.

Of equal importance is the role of automation in pallet management. A notable implementation involved automated guided vehicles (AGVs) that transported pallets efficiently. This technology reduced manual handling by 50%, leading to fewer injuries and a more focused workforce. However, some firms faced challenges with initial integration costs and training. These barriers are real, and many companies acknowledged that overcoming the learning curve was essential for long-term scalability.

Furthermore, the shift towards climate-conscious practices influenced storage choices. A warehouse that utilized eco-friendly materials for racking systems saw a 10% increase in customer satisfaction. Yet, they admitted that balancing sustainability with cost-effectiveness remained a tricky line to walk. Each case highlighted the complex landscape of pallet storage solutions, where success often intertwined with ongoing learning and adaptation.

Related Posts

-

2026 How to Choose the Right Uline Pallet Racks for Your Warehouse?

-

Best 10 Pallet Racking Solutions in Melbourne for Efficient Storage

-

Top 5 Benefits of Push Back Racking for Optimizing Warehouse Space

-

10 Expert Tips to Maximize Storage Efficiency with Uline Pallet Racks

-

Top Benefits of Efficient Pallet Storage Solutions for Your Warehouse

-

What is Pallet Shelving and How Can It Optimize Your Storage Solutions

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More