WSS Blog

Follow our latest updates and thoughts on our industry2026 Best Storage Racking Solutions for Your Warehouse Needs?

In today's fast-paced warehousing environment, choosing the right storage racking is crucial. Storage racking systems greatly enhance organization and efficiency. They help maximize space and streamline operations. However, many businesses struggle with the best solutions for their unique needs.

The options available can be overwhelming. Various factors come into play, such as load capacity and aisle width. A tailored approach is necessary. What works for one warehouse may not suit another. It’s vital to assess your specific requirements carefully. Maybe the current setup is not yielding desired results. Reflecting on existing systems can reveal areas for improvement.

Investing in the right storage racking is more than just purchasing racks. It involves thoughtful consideration and planning. With proper guidance, warehouses can transform. Enhanced storage can lead to increased productivity. But, not all solutions are perfect or easy to implement. Users must remain open to adapting their strategies.

Types of Storage Racking Systems Suitable for Warehouses

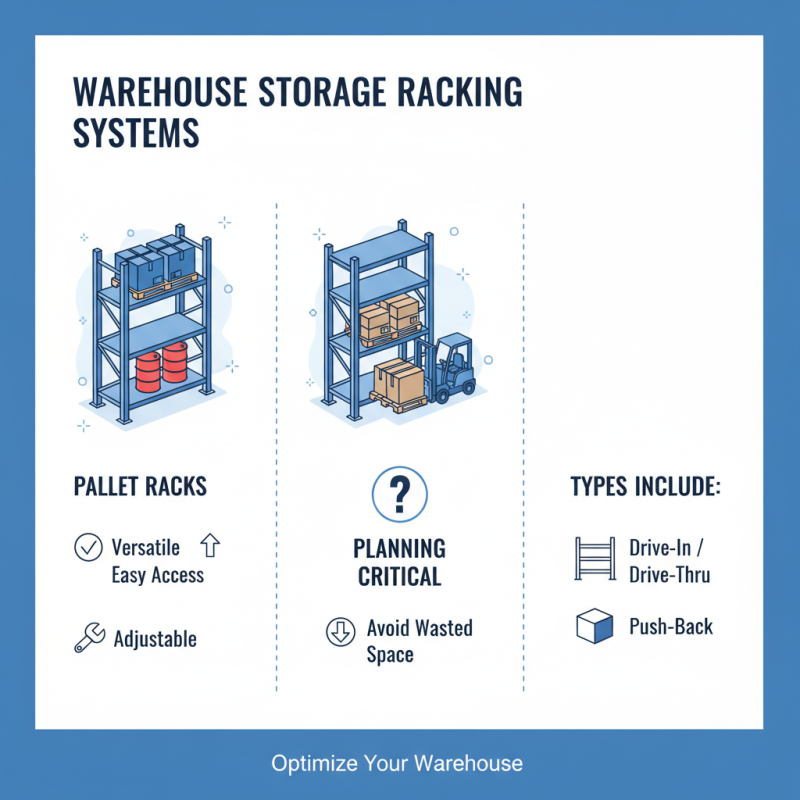

When selecting storage racking systems for warehouses, it’s essential to understand the different types available. Pallet racks are popular for their versatility. They enable easy access to pallets, making inventory management seamless. These racks can be adjusted to accommodate various pallet sizes. However, they require careful planning to avoid wasted space.

Another option is shelving systems. These are ideal for smaller items and can often be customized. They facilitate better organization and quick retrieval. Mesh shelving, for example, allows visibility for quick stock checks. Some may find shelving difficult to move when organization needs change, leading to potential inefficiencies.

Lastly, consider drive-in racks. These are designed for high-density storage. They maximize vertical space, allowing more goods in less area. Yet, if not managed properly, they can create issues with accessibility. A careful balance is necessary to mitigate challenges in maintaining stock flow. Make sure to analyze your specific needs before deciding on a system.

Factors to Consider When Choosing Storage Racking Solutions

When selecting storage racking solutions, several critical factors come into play. Understanding your warehouse's specific needs is paramount. For instance, consider the types of products you store. Heavy goods require durable racking systems. According to recent industry reports, 45% of warehouses facing inefficiencies didn't assess their product types effectively.

Space utilization is another factor. Many warehouses are underutilized due to poor racking choices. Studies indicate that implementing high-density racking can increase storage capacity by 30%. However, an overemphasis on density can lead to accessibility problems. A well-balanced approach is necessary.

Safety must not be overlooked. A staggering 31% of workplace injuries are linked to inadequate racking systems. Regular inspections and proper training can mitigate these issues. Nevertheless, some facilities still ignore these precautions. Reflecting on existing setups can reveal hidden flaws and opportunities for improvement.

2026 Best Storage Racking Solutions for Your Warehouse Needs

| Storage Racking Type | Load Capacity (lbs) | Height (ft) | Width (ft) | Depth (ft) | Best For |

|---|---|---|---|---|---|

| Selective Racking | 3,500 | 10 | 4 | 3 | General Storage |

| Drive-In Racking | 5,000 | 15 | 3 | 6 | High Density Storage |

| Pallet Flow Racking | 4,000 | 12 | 4 | 4 | FIFO Inventory Management |

| Cantilever Racking | 6,000 | 14 | 5 | 3 | Long & Bulky Items |

| Mobile Racking | 4,500 | 16 | 5 | 4 | Space Optimization |

Maximizing Space Efficiency with Innovative Racking Designs

Maximizing space efficiency in warehouses is vital. Innovative racking designs can transform how you utilize your space. Tall, vertical racks make the most out of small areas. Adjustable shelving allows for varying item sizes. This flexibility is key for diverse inventory.

Consider your workflow. Design your racking system to align with your picking process. Placement matters. Items that move quickly should be easily accessible. Position slow-moving items further away. Analyze traffic patterns for optimal layout decisions.

Tips: Regularly assess your racking system's performance. Look for areas of congestion. Adjust layouts as needed to improve efficiency. Invite team feedback on access and usability. Sometimes the best ideas come from those who use the space daily.

Safety Standards and Best Practices for Warehouse Racking

When considering warehouse racking, safety should always be a priority. Each type of racking system comes with its own set of safety standards. For example, pallet racking must be securely anchored to the floor. Regular inspections help identify risks. Inspectors often check for bent beams and unstable shelves. These small issues can lead to larger problems.

Proper training is essential. Workers must know how to use forklifts and navigate narrow aisles. Sometimes, they might feel rushed or unsure. That’s when accidents happen. A culture of safety can reduce risks significantly. Encourage employees to speak up about safety concerns. Create an open environment where feedback is welcomed.

Adopting best practices is crucial. Labeling storage areas can minimize confusion. Use color coding to highlight hazardous zones. However, not all companies implement these practices consistently. Regular updates to protocols can be beneficial. Reflecting on past incidents is crucial for growth. Assessing failures leads to improvements in safety and functionality.

2026 Best Storage Racking Solutions for Your Warehouse Needs

This bar chart represents the popularity of various storage racking solutions for warehouses in 2026, illustrating how each method is utilized within the industry.

Future Trends in Warehouse Storage Racking Solutions for 2026

As we approach 2026, the future of warehouse storage racking solutions is becoming increasingly pivotal. Industry reports suggest that the global warehouse racking market is expected to grow at a CAGR of around 7% in the coming years. This growth is driven by the rise of e-commerce and next-day delivery demands. Many warehouses are under pressure to maximize space and efficiency.

Automation will play a key role in transforming racking solutions. Automated storage and retrieval systems (AS/RS) are gaining popularity. These systems increase accuracy and reduce manual handling. However, the initial setup costs can be high. Many companies will need to evaluate the long-term benefits versus upfront investments.

Another trend is the shift towards customizable storage systems. Companies are recognizing the importance of adapting racking solutions to their unique needs. Beams, shelves, and pallet configurations vary widely. However, some companies struggle with space optimization. Data shows that poorly planned racking layouts can lead to a 30% loss in storage efficiency. This reality insists on the need for careful planning and ongoing reflection on operational processes.

Related Posts

-

Top 10 Warehouse Shelving Solutions for Optimal Space Utilization?

-

Top 10 Warehouse Pallet Racks to Optimize Your Storage Space in 2025

-

How to Choose the Right Storage Racking for Your Warehouse Needs?

-

Why Commercial Racking is Essential for Efficient Warehouse Management

-

2025 Top 10 Benefits of Push Back Racking for Efficient Warehouse Storage

-

10 Expert Tips to Maximize Storage Efficiency with Uline Pallet Racks

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More