WSS Blog

Follow our latest updates and thoughts on our industryHow to Choose the Best Pallet Racking System for Your Warehouse Needs

In today’s fast-paced industrial landscape, selecting the right pallet racking system is crucial for optimizing warehouse efficiency and maximizing storage capacity. With the global warehousing and logistics market projected to reach $1.2 trillion by 2025, the importance of choosing an effective pallet racking solution cannot be overstated. According to a report by Technavio, the demand for effective storage solutions is driven by the increasing need for space optimization as e-commerce continues to expand rapidly, pushing warehouse operators to rethink their inventory management strategies.

A well-designed pallet racking system not only enhances retrieval times but also helps in minimizing operational costs. For instance, research conducted by the Warehousing Education and Research Council (WERC) indicates that efficient racking systems can lead to a reduction in labor costs by as much as 20% due to improved accessibility and workflow. As businesses strive to meet the ever-changing demands of their customers, understanding the specific requirements of their warehouse operations and how various pallet racking configurations can address those needs is essential for long-term success. In this context, choosing the right pallet racking system becomes a strategic decision that contributes significantly to a warehouse's overall productivity and effectiveness.

Understanding Different Types of Pallet Racking Systems

When selecting a pallet racking system for your warehouse, it's essential to understand the various types available, as each design serves specific needs and functionalities. The most common type is selective racking, which allows easy access to all pallets, making it ideal for warehouses with a wide variety of products. This system maximizes storage density, as it can accommodate different pallet sizes and weights, though it may require more aisle space for operation.

Another type is drive-in racking, which is designed for high-density storage. This system enables forklifts to drive directly into the racking structure, allowing for the storage of multiple pallets in a single lane. It is best suited for companies that handle large quantities of a few products, as it utilizes space efficiently but restricts access to pallets at the back until those in front are removed. Additionally, push-back racking provides a balance between accessibility and storage density, allowing pallets to be stored in a slightly sloped system that lets the back pallets push forward as those in front are retrieved. Understanding these different pallet racking systems is crucial in making an informed decision that aligns with your warehouse needs.

How to Choose the Best Pallet Racking System for Your Warehouse Needs - Understanding Different Types of Pallet Racking Systems

| Type of Racking | Description | Advantages | Disadvantages | Best Used For |

|---|---|---|---|---|

| Selective Pallet Racking | The most common type, allowing direct access to each pallet. | Easy to install, high accessibility. | Lower storage density, requires more aisle space. | Warehouses with diverse SKUs. |

| Drive-In Racking | A high-density storage solution where forklifts enter the rack structure. | Maximizes storage space, efficient for large quantities of fewer SKUs. | Limited access; first in, last out system. | Bulk storage facilities. |

| Push Back Racking | Pallets are loaded onto carts that slide back when new pallets are added. | High density, easy access to pallets. | Requires specific forklifts, limited to two to six pallets deep. | Storing various SKUs with similar turnover rates. |

| Flow Racking | Utilizes gravity to move pallets from the loading side to the picking side. | Automatic FIFO inventory management, high density. | Higher upfront cost, specific design needed. | Perishable goods, high-rotation inventory. |

Assessing Your Warehouse Space and Inventory Needs

Assessing your warehouse space and inventory needs is crucial in selecting the most suitable pallet racking system. Start by accurately measuring your warehouse dimensions, including the height, width, and length of the storage area. It's essential to identify any structural limitations or obstacles such as columns, doors, and ventilation systems that might affect racking installation. A thorough understanding of your available space will allow you to choose a racking system that maximizes your storage capacity while ensuring compliance with safety regulations.

Next, analyze your inventory types and quantity. Consider the size, weight, and turnover rates of the products you handle. High-turnover items may necessitate a more accessible racking solution, such as selective racking or drive-in racks, which facilitate efficient picking processes. Conversely, for large or less frequently accessed items, bulk storage options may be more appropriate. By aligning your racking choice with inventory characteristics, you can optimize your warehouse layout for both efficiency and ease of use, ensuring that your operations run safely and s smoothly.

Evaluating Load Capacity and Safety Standards

When selecting a pallet racking system for your warehouse, evaluating load capacity and safety standards is paramount. Load capacity refers to the maximum weight that each rack can support without risking failure. To determine the appropriate capacity, consider the weight of the items you will store, as well as the configuration of your racking system. Overloading racks can lead to structural damage or safety hazards, making it crucial to choose a system designed to handle your specific requirements.

Safety standards play a vital role in ensuring a secure working environment. Familiarize yourself with local and international regulations that govern warehouse safety practices. Proper installation, regular maintenance, and employee training on safe handling procedures are essential components of compliance with these standards. Utilizing features such as safety locks, proper aisle spacing, and load guides can further enhance the stability of your pallet racking system, ensuring both operational efficiency and the safety of your workforce.

Load Capacity of Different Pallet Racking Systems

Considering Accessibility and Picking Efficiency

When selecting a pallet racking system, considering accessibility and picking efficiency is crucial for optimizing warehouse operations. Accessibility refers to how easily personnel can reach items stored within the racking system. A well-designed layout will facilitate quick access to products, minimizing the time workers spend searching for and retrieving items. Systems such as selective racking allow for immediate access to every pallet, which is especially beneficial for warehouses handling a diverse range of products with varying turnover rates.

Picking efficiency, on the other hand, is about streamlining the process of order fulfillment. It involves examining how the racking system influences the speed and accuracy of picking items for shipment. For instance, systems like flow racking can enhance picking efficiency by employing gravity to move products toward the front of the rack. This setup reduces the distance required to travel when picking items, hence improving overall productivity. Additionally, incorporating technology such as barcode scanning or automated inventory management can further enhance picking accuracy within the chosen racking system. Fostering a balance between accessibility and efficiency ensures that warehouses remain agile and responsive to fluctuating demands.

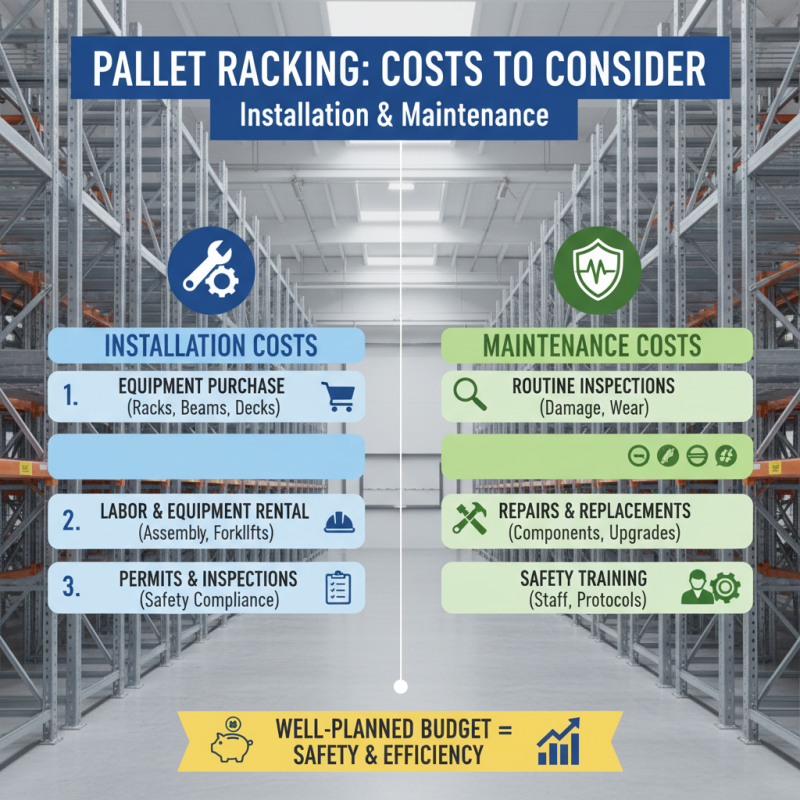

Budgeting for Installation and Maintenance Costs

When selecting the best pallet racking system for your warehouse needs, it's essential to factor in the costs associated with installation and maintenance. A well-planned budget not only covers the initial purchase of the racking system but also anticipates ongoing maintenance expenses. Consider how often you will need to replace components or perform routine checks to ensure safety and efficiency. Allocating funds for these aspects can help avoid unexpected financial strains down the line.

Tips for budgeting effectively include researching various racking options and their associated costs. Look into potential discounts for bulk purchases or consider investing in a slightly more expensive, durable system that may lower your maintenance costs over time. Additionally, do not overlook the importance of professional installation; while it may seem like an extra expense, incorrect setup can lead to greater costs in repairs or even accidents.

Another important factor to consider is the long-term adaptability of your racking system. As your warehouse needs grow, will your chosen system be able to accommodate changes without requiring extensive additional investments? Planning for scalability can save you significant money in the long run, making it a critical consideration during the budgeting process.

Related Posts

-

Best 10 Pallet Racking Solutions in Melbourne for Efficient Storage

-

Top 5 Benefits of Push Back Racking for Optimizing Warehouse Space

-

Top 10 Warehouse Pallet Racks to Optimize Your Storage Space in 2025

-

2025 How to Optimize Your Warehouse Space with Industrial Pallet Racks

-

Why You Should Choose Dexion Pallet Racking for Efficient Warehouse Storage

-

Why Choose Pallet Racking in Brisbane for Your Warehouse Storage Needs

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More