WSS Blog

Follow our latest updates and thoughts on our industryHow to Choose the Right Heavy Duty Pallet Racks for Your Warehouse Needs?

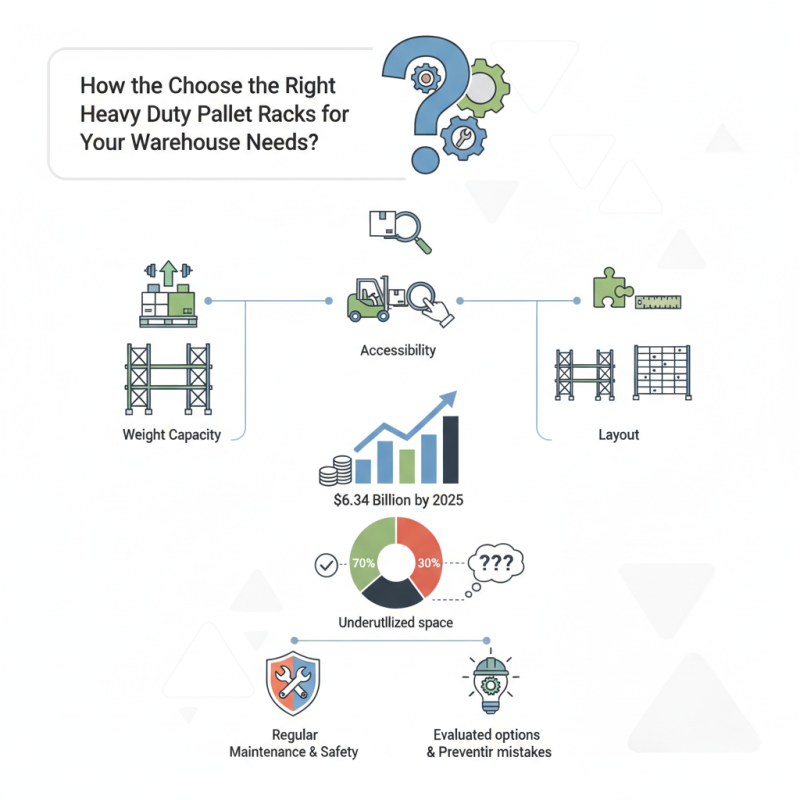

Choosing the right heavy duty pallet racks is crucial for optimizing warehouse operations. The global market for pallet racks is projected to reach $6.34 billion by 2025, highlighting their importance in logistics. Each warehouse has specific needs that influence rack selection.

Consider the weight capacity, accessibility, and layout. Heavy duty pallet racks can support heavy loads, but their design must suit the warehouse space effectively. It's not just about storing goods; it's about facilitating efficiency. Research indicates that 30% of warehouse space is underutilized. This raises questions about rack configuration.

Choosing the ideal heavy duty pallet racks is challenging. Not every rack is suitable for every inventory type. Regular maintenance is necessary to ensure safety and longevity. Evaluating options and understanding warehouse dynamics can prevent costly mistakes.

Understanding Your Warehouse Storage Requirements

Understanding your warehouse storage requirements is essential for choosing the right heavy-duty pallet racks. Each warehouse is unique. Consider factors like available space, load capacity, and accessibility. This helps in selecting racks that fit well in the environment. Ideal storage solutions maximize the use of vertical space. Think about your inventory types. Are they light or heavy? Choosing racks suited for these weights can prevent safety hazards and optimize efficiency.

Layout matters, too. A good design facilitates smooth workflow and quick access to items. Narrow aisles might increase storage density but can hinder movement. It's a delicate balance. Reflect on your team’s operations and flow of goods. Do employees struggle to reach items? If so, your rack choice needs reevaluation.

Finally, remember that decisions can evolve. As your warehouse grows, storage needs will change. Regularly reassess your setup. What works today may not be ideal tomorrow. Keeping a flexible mindset is crucial in warehouse management. Make adjustments as necessary for continued efficiency and safety.

How to Choose the Right Heavy Duty Pallet Racks for Your Warehouse Needs?

| Storage Requirement | Recommended Rack Type | Load Capacity (lbs) | Typical Use Case |

|---|---|---|---|

| High Density Storage | Drive-In Racks | 20,000 | Perishable Goods, Raw Materials |

| Standard Bulk Storage | Selective Racks | 3,000 | General Warehouse Storage |

| Heavy Equipment Storage | Cantilever Racks | 6,000 | Lumber, Pipes, Long Products |

| Easy Access and Visibility | Push Back Racks | 16,000 | Retail Warehouse, Distribution Centers |

| Bulkier Items | Mobile Racks | 4,000 | Museum Storage, Archives |

Types of Heavy Duty Pallet Racks Available

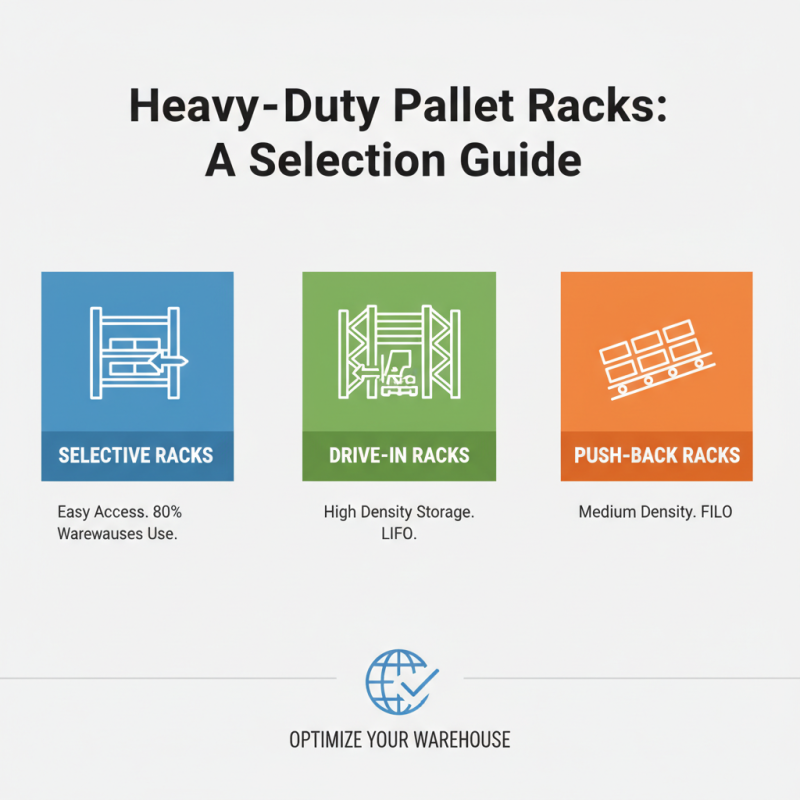

When selecting heavy-duty pallet racks, it is crucial to understand the types available. Common models include selective racks, drive-in racks, and push-back racks. Selective racks are versatile and allow easy access to individual pallets, supporting dynamic warehouse environments. Reports indicate that around 80% of warehouses use this type due to its flexibility.

Drive-in racks are designed for maximum storage density. They allow for multiple pallets stored in-depth, ideal for high-volume goods. However, accessing specific pallets can be challenging. Data shows that these systems can increase storage capacity by up to 60%. Yet, that is not without trade-offs. Often, the layout requires careful planning.

Push-back racks combine dense storage with accessibility. They use a unique design where pallets slide back as new ones are added. This ensures an efficient use of space while maintaining easy access. However, they may require more upfront investment and training for employees. A study suggests that while initial costs can be higher, the long-term efficiency justifies the expense.

Selecting the right type involves balancing costs with operational needs. Evaluating the volume of goods and ease of access will dictate the best choice for a warehouse.

Evaluating Load Capacity and Durability Specifications

When selecting heavy-duty pallet racks, evaluating load capacity is crucial. Every warehouse has unique storage needs. Understand the maximum weight your racks will bear. This involves not only the products' weight but also how they are arranged. Overloading can lead to accidents or rack failures, causing damage and injury.

Durability is equally important. Look for racks constructed from robust materials. Steel is a common choice due to its strength. Check for protective coatings that resist corrosion. In a humid warehouse, even small rust spots can compromise integrity. Questions to consider include: How often will the racks be moved? Will they be exposed to chemicals or moisture? Each scenario affects long-term durability.

Remember, not all racks are created equal. Some may promise high load capacities but can falter under real conditions. Reflect on past experiences with storage systems. Did they meet your expectations? Be wary of overly optimistic specifications. Testing the racks under actual working conditions can help avoid issues later on.

Considerations for Installation and Warehouse Layout

When selecting heavy-duty pallet racks, the warehouse layout is crucial. A well-planned layout improves efficiency and safety. Research from the Warehouse Efficiency Report shows that a decent layout can boost picking speeds by up to 25%. If racks are poorly placed, it can create bottlenecks.

Consider the flow of goods. Items that are frequently accessed should be located close to loading/unloading areas. Avoid overcrowding aisles. This practice can lead to accidents and slow down operations. Stick to a design that allows for easy navigation. Utilize vertical space effectively, but ensure the top racks are accessible and safe to reach.

Tips: Measure your space before installation. Get the right dimensions. Even small errors can lead to significant issues. Always leave room for expansion. Warehouse needs may change over time. It’s wise to plan for the future. Remember, a flexible design often yields the best long-term results.

Maintenance and Safety Tips for Heavy Duty Pallet Racks

Maintaining heavy-duty pallet racks is crucial for warehouse safety. According to industry reports, nearly 20% of workplace injuries involve racking systems. Regular inspections can help prevent accidents. Look for signs of wear and tear, such as bent beams or damaged uprights. Identifying these issues early can save time and money, and most importantly, protect your employees.

Tip: Implement a weekly inspection routine. Designate a responsible person to check the racks. Document findings thoroughly to track changes over time. This proactive approach helps in maintaining safety standards.

Safety features shouldn't be overlooked. Ensure that your pallet racks are properly anchored. This reduces the chances of tipping. Additionally, training staff on how to load racks safely is vital. Many warehouses fail to provide adequate training, leading to dangerous situations. Regular safety drills can enhance awareness among employees.

Tip: Use safety straps or netting. These can secure pallets and prevent falls. Ensure that heavy items are stored on lower levels. This minimizes the risk of accidents.

Choosing the right racks is important, but maintaining them is essential. Effective management of pallet racks improves safety. It is not just about selecting the right equipment, but also about consistent upkeep. Without proper maintenance, a warehouse can turn into a hazardous zone.

Related Posts

-

Why Commercial Racking is Essential for Efficient Warehouse Management

-

2025 Top 10 Benefits of Push Back Racking for Efficient Warehouse Storage

-

2026 Best Storage Racking Solutions for Your Warehouse Needs?

-

Top 10 Longspan Shelving Solutions for Maximizing Storage Efficiency

-

10 Best Warehouse Shelving Solutions for Optimal Space Utilization?

-

How to Choose the Right Pallet Rack Beams for Your Warehouse Storage Needs

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More