WSS Blog

Follow our latest updates and thoughts on our industry10 Essential Tips for Choosing the Right Pallet Racking System?

Choosing the right pallet racking system can significantly impact your warehouse efficiency. According to John Smith, a leading expert in logistics, "Selecting the correct racking system is crucial for maximizing space and productivity." His insight reflects the importance of this decision in an industry where every square foot counts.

Many factors influence this choice. The weight capacity, layout, and type of products stored all matter. However, it's easy to overlook details. For instance, some businesses focus only on cost. They may ignore long-term benefits. A cheap system can lead to safety hazards and increased downtime. These risks can be costly.

Understanding your specific needs is vital. Will your inventory change frequently? Are you handling heavy loads? Every situation is unique. Investing time in evaluating options can pay off. A well-suited pallet racking system can streamline operations and enhance workflow. This process is not just about racks; it's about creating a more effective working environment.

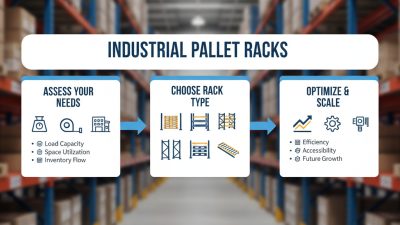

Understanding Your Storage Needs: Assessing Space and Inventory Requirements

Assessing your storage needs is crucial when choosing a pallet racking system. Start by measuring your available space. Consider both height and width. Ensure there's room for easy access and movement. A cramped area can lead to inefficiencies. Analyze your inventory requirements next. What types of items will you store? Heavy loads need robust racking. Smaller items might benefit from selective shelving.

Capacity is key. Take inventory count seriously. If you have seasonal spikes, plan for that. Remember, overloading racks is unsafe. It’s easy to overlook weight limits. Prioritize a system that allows for flexibility. As inventory changes, your racking should adapt too. Being too rigid can create headaches down the line. Make adjustments before problems arise. Reflect on your current operations. Are there bottlenecks? Address them early. Finding the right balance between space and stock can drive efficiency.

10 Essential Tips for Choosing the Right Pallet Racking System

| Tip Number | Tip Description | Considerations | Benefits |

|---|---|---|---|

| 1 | Evaluate Your Space | Measure the height and width of your storage area. | Maximize storage efficiency. |

| 2 | Assess Your Inventory | Determine the size and weight of items to be stored. | Ensure safety and stability. |

| 3 | Select Appropriate Racking Type | Choose between selective, drive-in, or pallet flow racking. | Optimize access and space usage. |

| 4 | Consider Future Storage Needs | Plan for potential expansion or changes. | Reduce future costs and disruptions. |

| 5 | Check Load Capacity | Ensure racking can support the maximum load. | Avoid structural failure and accidents. |

| 6 | Look for Adjustable Systems | Choose racking that can be adjusted to different heights. | Enhance flexibility and usage of space. |

| 7 | Evaluate Safety Features | Check for safety standards and certifications. | Protect employees and inventory. |

| 8 | Consider Accessibility | Plan aisles for forklift movement and picking efficiency. | Improve workflow and reduce delays. |

| 9 | Get Professional Advice | Consult with storage solution experts. | Tailored solutions for specific needs. |

| 10 | Review and Revise | Regularly assess storage systems for optimization. | Ensure long-term effectiveness and efficiency. |

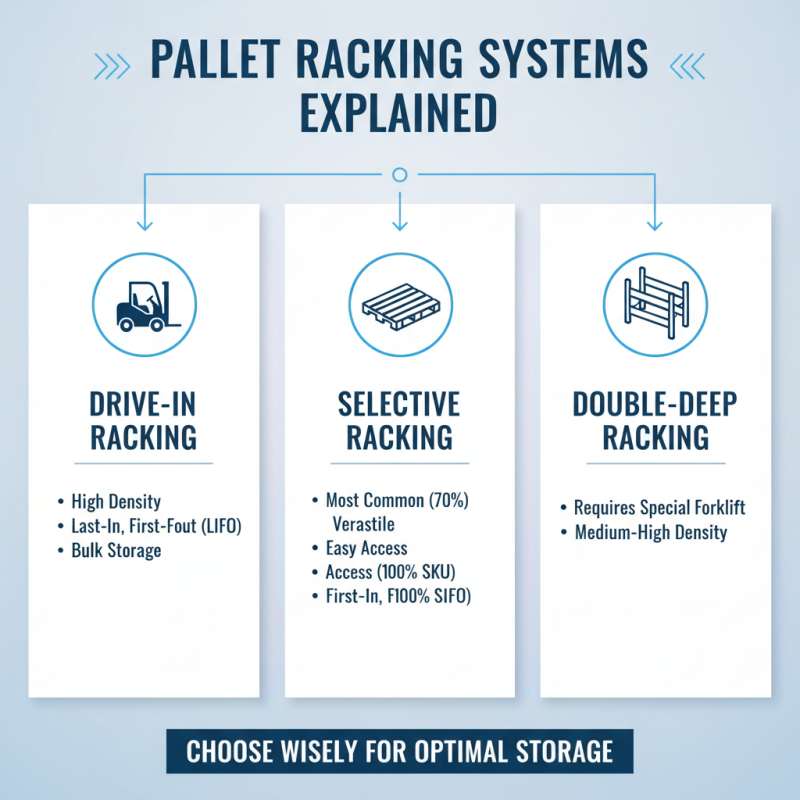

Types of Pallet Racking Systems: An Overview of Options Available

When selecting a pallet racking system, understanding the available types is crucial. There are various options tailored for different storage needs. Drive-in, selective, and double-deep racking systems are among the most popular choices. According to industry reports, selective racking is widely used, accounting for approximately 70% of all racking systems due to its versatility.

Drive-in racking allows for high-density storage. It is suitable for large quantities of similar items. However, identifying specific pallets can become challenging. On the other hand, double-deep racking offers better access to pallets than drive-in systems. This can enhance efficiency but may require specialized forklifts for operation.

Tip: Consider your inventory turnover rate. High-turnover items require different systems than low-turnover products. This can help in maximizing warehouse efficiency. Additionally, always evaluate the space available and the height of your warehouse. It's essential to balance density with accessibility. Having a detailed layout plan can prevent costly mistakes in installation.

Evaluating Load Capacity: Ensuring Safety and Efficiency Standards

When selecting a pallet racking system, evaluating load capacity is crucial. Each pallet rack must meet specific structural standards. It's essential to calculate the weight of items stored. Overloading can lead to failure. An unsafe rack can cause accidents or product damage. Begin by checking the load limits specified by your racking system. Each beam and column has its ratings. These numbers are not arbitrary; they are based on rigorous testing.

Consider the layout of your warehouse. Different areas may require different capacities. An aisle with high turnover might need more robust racking. Think about future needs too. Business growth could change your requirements. Informal discussions with your team can reveal insights. They might notice issues that can be overlooked.

After selecting a system, monitor its performance regularly. Look for signs of stress or wear. Small cracks or bending are red flags. Regular inspections help maintain safety. Sometimes, it’s easy to overlook these details in a busy operation. Maintaining efficiency requires vigilance and reflection. Keep an eye on your racks. Safety is not just a checkbox.

Load Capacity Evaluation of Different Pallet Racking Systems

Consideration of Accessibility: Influencing Warehouse Workflow

When selecting a pallet racking system, accessibility is a key factor that can significantly influence warehouse workflow. According to a report by the Warehousing Education and Research Council, inefficient racking systems can cause increased pick times by up to 30%. This inefficiency not only slows down operations but also raises labor costs. Tight aisles can make it difficult for lift trucks to maneuver. This leads to potential accidents and delays.

Proper accessibility ensures smooth operations. This means considering the width of aisles and the layout of storage racks. A wider aisle allows better movement for equipment and personnel. Research suggests that a well-planned racking system can improve workflow efficiency by up to 25%. When accessibility is ignored, it can even impair inventory management. Workers may struggle to locate items quickly, leading to errors and wasted time.

Moreover, storage height should be assessed. High racks might seem ideal for maximizing space, but they can hinder accessibility. Safety becomes a concern too. Employees may be at risk when retrieving products from elevated storage. Consequently, while aiming for space efficiency, it’s crucial to balance height with accessibility. Each decision in pallet racking should consider how it affects daily operations and overall productivity.

Budgeting for Pallet Racking: Cost Factors and Long-Term Investment

When budgeting for a pallet racking system, understanding cost factors is crucial. The initial investment can vary greatly based on size, capacity, and materials. It is vital to estimate space requirements accurately. Overestimating needs can lead to unnecessary expenses. Conversely, underestimating can cause inefficiencies in storage and retrieval processes.

Long-term investment is another key aspect. Quality materials might cost more upfront but can save money later. Regular maintenance and the durability of the system affect its longevity. Choosing a design that maximizes storage space can also enhance productivity. However, it can be challenging to balance immediate costs with future savings.

Consider potential warehouse changes. Flexibility in your racking system can lead to adjustments without significant reinvestments.

Related Posts

-

Top 2025 Pallet Racking Solutions in Melbourne for Your Warehouse Needs

-

Best 10 Pallet Racking Solutions in Melbourne for Efficient Storage

-

How to Choose the Right Warehouse Storage Racks for Your Business Needs

-

How to Choose the Best Pallet Racking System for Your Warehouse Needs

-

How to Choose the Right Industrial Pallet Racks for Your Warehouse Needs

-

How to Choose the Right Industrial Pallet Racks for Your Warehouse Needs?

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More