WSS Blog

Follow our latest updates and thoughts on our industryTop 10 Warehouse Shelving Solutions for Optimal Space Utilization?

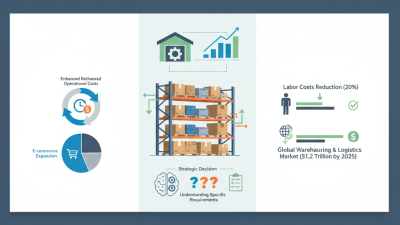

Warehouse shelving is a vital component of effective inventory management. With proper shelving, businesses can enhance their space utilization and streamline operations. According to a report by the Material Handling Industry of America, efficient shelving systems can improve space usage by as much as 30%. This statistic highlights the potential impact of selecting the right shelving solutions.

Many companies underestimate the importance of optimizing warehouse shelving. When faced with limited space, inefficient shelving choices can lead to clutter and disorganization. In fact, a study from the Warehouse Education and Research Council indicates that poor shelving can increase retrieval times, negatively affecting productivity. It’s necessary to reflect on how every inch of space is used, ensuring that it serves a purpose.

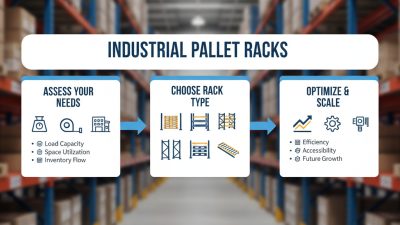

Choosing the right warehouse shelving requires careful consideration. Factors such as weight capacity, material type, and layout should all be evaluated. The challenge is to balance cost-effectiveness with functionality. As businesses scale, it is common to overlook the adaptability of shelving. Revisiting and refining storage solutions can lead to substantial gains in operational efficiency.

Key Factors Influencing Warehouse Shelving Selection

When it comes to selecting warehouse shelving, several key factors play a crucial role. The weight capacity of the shelving system is essential. Consider the heaviest items you will store. Shelves must support these loads without bending or breaking. This often requires thorough inspections, which can be time-consuming.

Another factor is the size of the shelving units. Measure your available space accurately. Oversized shelves waste valuable room. Conversely, undersized shelves can lead to inefficient stacking. Ensure that shelves allow easy access to items. Wide aisles can improve picking speed but reduce shelf space.

Tips: Think about vertical space usage. High shelves maximize floor area but create challenges for retrieval. Invest in ladders or lifts. Regularly reassess your shelving needs as inventory changes. What worked last year might not suit your current items. Flexibility is essential to adapt.

Also, consider the material of the shelves. Metal shelves are durable but can rust in humid conditions. Wooden shelves can hold weight well but may not be as sturdy. Reflect on the longevity and the potential cost of replacement.

Top 10 Warehouse Shelving Solutions for Optimal Space Utilization

| Shelving Solution | Material | Weight Capacity (lbs) | Dimensions (L x W x H) | Adjustability | Ideal Use Case |

|---|---|---|---|---|---|

| Heavy-Duty Racking | Steel | 4000 | 48 x 36 x 72 in | Yes | Bulk storage |

| Cantilever Racking | Steel | 3000 | 72 x 48 x 96 in | Yes | Long materials |

| Boltless Shelving | Steel | 1500 | 48 x 24 x 72 in | Yes | General storage |

| Mobile Shelving | Steel | 2000 | 72 x 36 x 84 in | Yes | High-density storage |

| Adjustable Pallet Racking | Steel | 5000 | 96 x 48 x 144 in | Yes | Palletized goods |

| Wire Shelving | Steel | 750 | 60 x 24 x 72 in | Yes | Food storage |

| High-Density Mobile Shelving | Steel | 3500 | 72 x 36 x 60 in | Yes | Space-saving |

| Utility Shelving | Plastic/Metal | 600 | 48 x 18 x 72 in | Limited | Light storage |

| Corner Shelving Units | Wood/Metal | 300 | 36 x 36 x 72 in | No | Corner storage |

| Plastic Bin Shelving | Plastic | 250 | 48 x 24 x 48 in | No | Small parts organization |

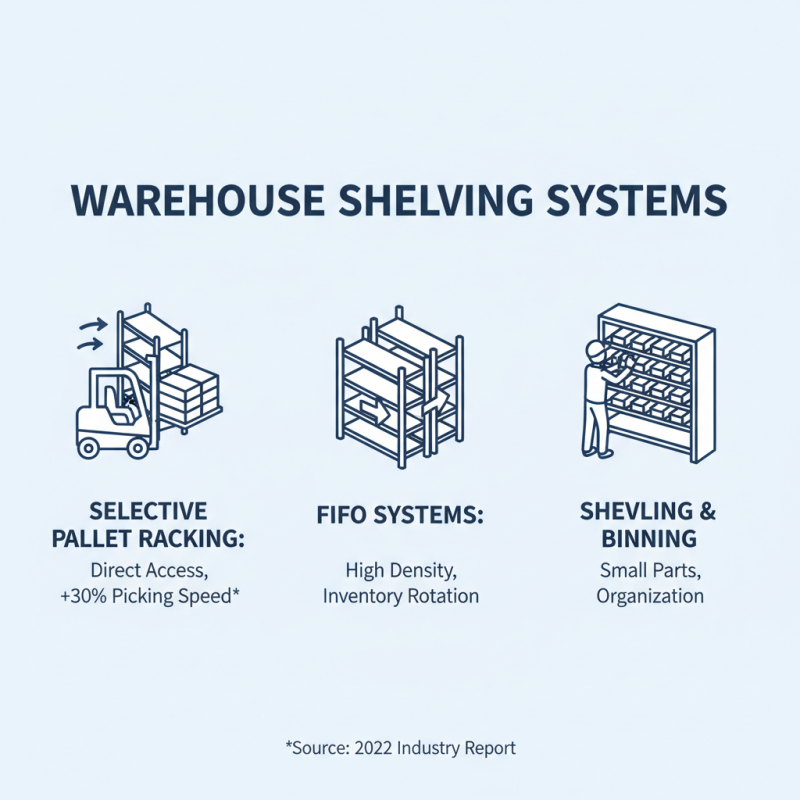

Types of Warehouse Shelving Systems and Their Benefits

When considering warehouse shelving systems, various options exist. Each type brings unique benefits. For instance, selective pallet racking allows direct access. A 2022 industry report shows it enhances order picking speed by 30%. This system works well in spaces with varying product sizes.

Drive-in shelving systems maximize vertical space. They utilize a “last-in, first-out” (LIFO) method. This design is ideal for high-density storage. However, it can complicate inventory rotation. Understanding your inventory flow is essential.

Tips: Regularly assess your inventory levels to choose the right shelving system. Inspecting the layout yearly can reveal underused spaces. Also, incorporate adjustable shelving to meet changing demands. Consider investing in a modular system. It can adapt to future needs, providing long-term flexibility.

Maximizing Vertical Space with Adjustable Shelving Solutions

Utilizing vertical space is crucial in warehouse environments. Adjustable shelving solutions can transform how space is used. According to industry data, effective shelving can increase storage space utilization by up to 40%. This optimization not only maximizes available space but also improves efficiency in operations.

Employing adjustable shelving allows for customized arrangements. Shelves can be repositioned to fit various product sizes. This adaptability means you can quickly adjust to inventory changes. Remember, proper spacing is vital. A gap of just a few inches between shelves may significantly affect accessibility. Keep your aisles clear to facilitate movement.

Tip: Regularly assess your shelving configuration. What works today may not work tomorrow. Pay attention to high-demand items. Ensure they are easily accessible. Reducing the time spent searching for products can greatly enhance productivity. Strive for a balance between storage and practicality. Consider the limits of your existing structures. Inefficient setups can lead to wasted time and increased frustration.

Implementing Safety and Compliance in Warehouse Shelving Design

When designing warehouse shelving, safety and compliance play crucial roles. Each shelving unit should conform to safety standards. This includes proper weight capacity for stored items. Overloading shelves can lead to accidents and damages. It’s critical to regularly inspect shelving for wear and tear. Failing to do so may result in a hazardous environment.

Additionally, the layout should promote safe navigation. Leave enough space for personnel to move freely. Aisles should be clearly marked for ease of access. Effective placement of signage can enhance awareness of safety protocols. Reflecting on past incidents in similar setups can provide valuable insights. Implementing feedback loops can improve overall safety measures.

Lastly, employee training is vital. Staff should understand how to use shelves safely. Regular workshops can reiterate safety procedures. Observing warehouse operations can reveal areas needing improvement. Continuous revision of safety practices can ensure compliance and protect workers.

Cost-Benefit Analysis of Different Shelving Options

When evaluating warehouse shelving options, a cost-benefit analysis is essential. Different shelving systems offer various advantages and limitations. For instance, static shelving may seem cheaper initially. However, it can be less efficient in utilizing vertical space compared to mobile shelving systems, which can double storage capacity in the same footprint.

According to industry data, companies can increase their storage efficiency by up to 50% by using modular shelving systems. The initial investment may be higher, but the return on investment can be substantial. Furthermore, while heavy-duty shelving can handle more weight, it might not be the best choice for lighter materials. Often, warehouses overlook balancing cost and actual needs.

Some companies report struggling with under-utilized space due to poor shelving choices. Others face productivity losses because of difficult access to items. These issues highlight the necessity of thoughtful planning. Every warehouse has unique demands. It’s crucial to analyze space requirements, item size, and access frequency. This reflection is vital for optimizing space and minimizing costs effectively.

Top 10 Warehouse Shelving Solutions for Optimal Space Utilization

Related Posts

-

Top 10 Warehouse Pallet Racks to Optimize Your Storage Space in 2025

-

Why You Should Choose Dexion Pallet Racking for Efficient Warehouse Storage

-

Top 10 Longspan Shelving Solutions for Maximizing Storage Efficiency

-

How to Choose the Right Industrial Pallet Racks for Your Warehouse Needs

-

How to Choose the Right Warehouse Storage Racks for Your Business Needs

-

How to Choose the Best Pallet Racking System for Your Warehouse Needs

We Value Your Privacy

We use cookies to personalise content and ads, provide social media features, and analyse our traffic.By clicking “Accept All Cookies”, you agree to the storing of cookies on your device to enhance site navigation, analyse site usage, and assist in our marketing efforts. You can manage your preferences by selecting “Cookie Settings” Accept All Reject Settings

Read More